A common in-the-field challenge now has a proven solution! New research funded by the Northwest Energy Efficiency Alliance (NEEA) and conducted by Larson Energy Research has redefined the minimum room volume requirement for an electric hybrid water heater (EHWH).

This study also demonstrated that simple venting and ducting techniques for small spaces, such as mechanical closets, can result in high levels of operating efficiency.

The Bottom Line: This research should give installers confidence that EHWHs installed in rooms with air volume less than 700 ft3 but greater than 450 ft3 will still result in significant savings from the installation.

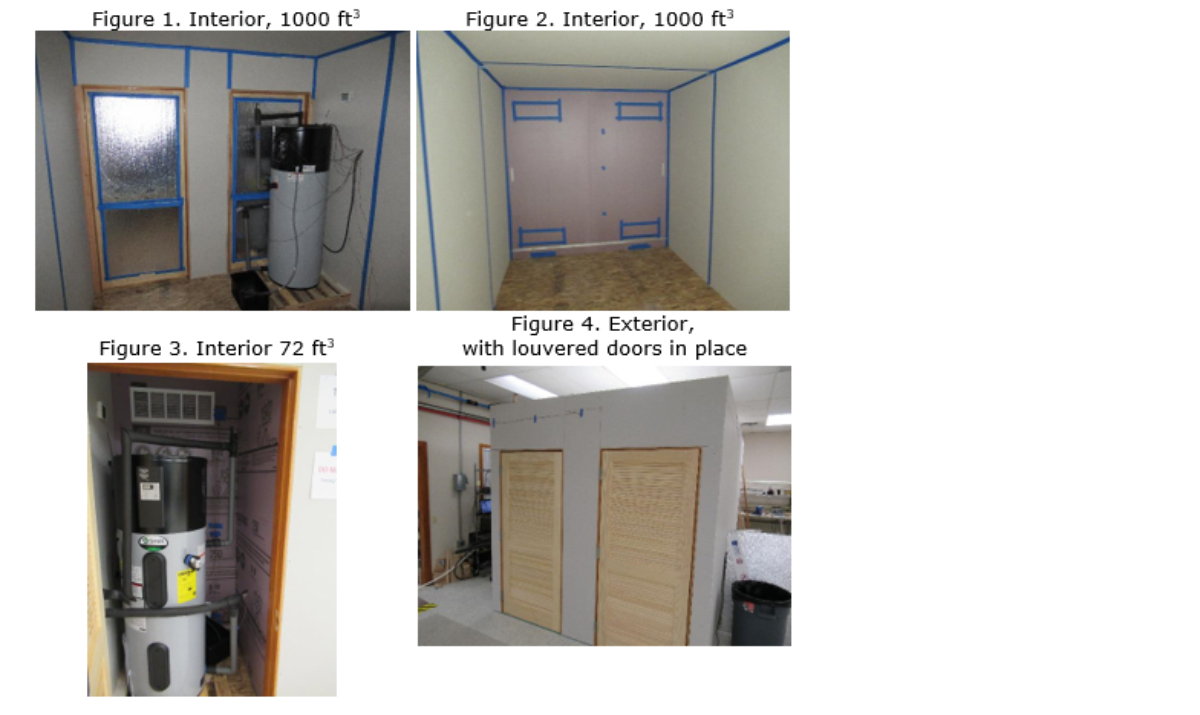

The experiment was constructed within a large, conditioned space in which the wall panels could be relocated to alter the volume of the space from varying increments between 1,000 ft3 to 72 ft3, as seen in Figures 1 - 4. Additionally, vents, louvers, and exhaust ducting could easily be installed and/or removed to create a variety of room configurations for testing.

The tank’s temperature, the compressor’s electrical measurements, and the heating element were measured through the entirety of the study, while the EHWH was subjected to various hot water draw patterns that simulated typical real-world hot water usage.

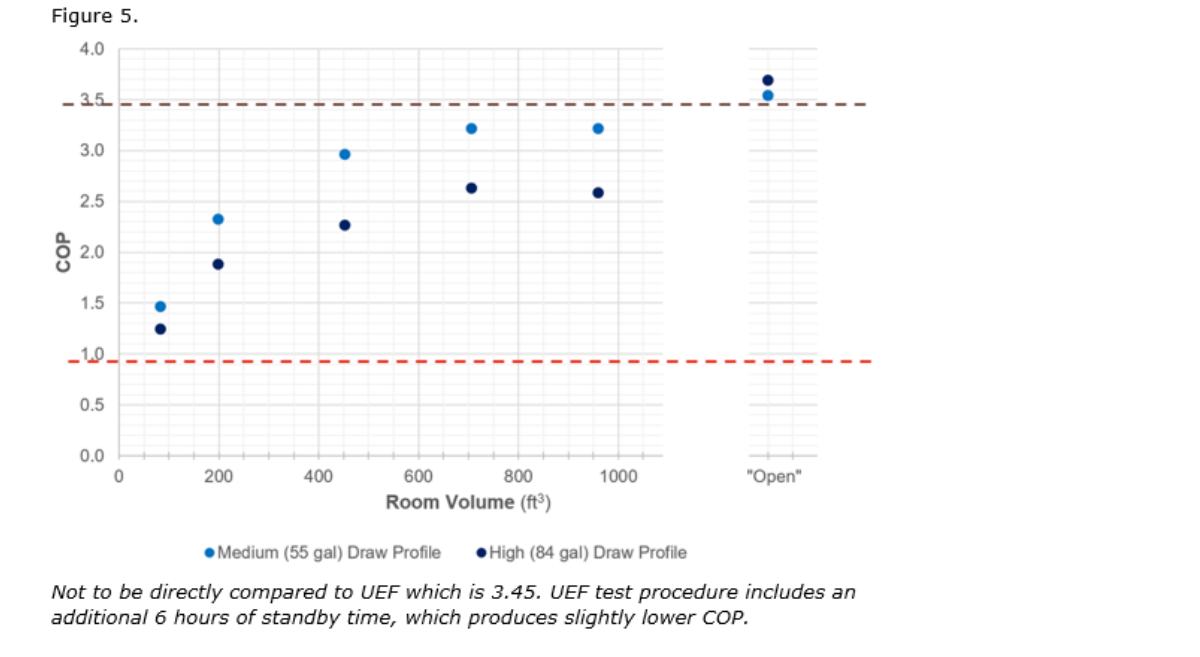

This study utilized the coefficient of performance (COP) instead of the uniform energy factor (UEF) due to the simplicity of the ratio and easy replicability in a research setting. COP can be defined as the amount of energy produced by the tank over the amount of energy consumed by the tank.

As seen in Figure 5 below, the impact of reducing the minimum room volume from 700 ft3 to 450 ft3 resulted in only a slight decrease in the COP, from 3.21 to 2.96 for a medium draw profile (55 gal), and 2.63 to 2.26 for a high draw profile (84 gal). The COP for both the medium draw profile and the high draw profile at 450 ft3 still remain well above that of a standard electric tank of less than 1.

The venting and ducting configurations assessed during this study additionally provided a means for overcoming the volume constraints of mechanical closets and other small spaces, of less than 450 ft3.

An EHWH uses driving forces of cold air (sinking) and a fan to move the air. The heater needs the make-up air to run through the heat exchanger to push the heat into the tank. For every cubic foot per minute (CFM) of air leaving the vent, 1 CFM is drawn into the heat pump compression zone. In condensing systems, the fan is used as the driving force.

Successful venting and ducting methods utilize a driving force to move air in and out of the space where an EHWH is located – if there is no driving force, there is no air movement, resulting in lower operating efficiency.

While the researchers tested multiple configurations, there were three scenarios that produced meaningful results and had little complication with installation:

In scenarios 1 & 2, the driving force of the small room results from the cool, dense air exhausted from the system, exiting out the lower vent, or the lower portion of the louvered door and then being replaced with room air entering the room through the upper vent, or the upper portion of the louvered door.

In scenario 3, the combination of the ducted exhaust air and a vent to provide air intake also functioned as a driving force, resulting in high COPs.

Resulting COP measurements for each scenario:

Note that placing vents only high (1.47) or only low (1.39) does not result in optimal air intake, because there is no driving force present.

Not only did the study prove that spaces smaller than 700 ft3 are suitable locations for EHWHs, but it also demonstrated through real world configurations that simple techniques of venting and ducting methods of spaces less than 450 ft3 can help to overcome room volume constraints and result in high levels of operating efficiency.

Complete details from this study can be found through the NEEA Product Council's recorded webinar presentation, and in the upcoming research paper, found on the Northwest Energy Efficiency Alliance's website. As NEEA continues developing solutions for confined spaces, please send any information and/or questions to gwickes@neea.org, and we will work with you to help solve your problems.

Be sure to check with each manufacturer on specific volumetric requirements and installation guidance for EHWHs.